Schubert Digital Packaging Machine Solutions

Last updated 7 years ago by pi-Team

Schubert flexible robotic packaging solutions go digital

Modular robotic packaging and product manipulation machines made in Germany

Germany’s Gerhard-Schubert GmbH is well respected throughout the world for its outstanding robotic flexible packaging solutions. The machine manufacturer is now presenting another step forward in digital packaging machine solutions for best performance.

Packaging processes become more and more complex due to higher product diversity and smaller batch sizes. Gerhard Schubert GmbH answers this trend with the principle of simplicity. To this end, the recognized market leader for digital packaging machines and out of the box robotic packaging and manipulation solutions has been using its own intelligent machine control system for decades.

New Generation of Packaging Machine Control System

The sixth generation of VMS packaging machine control is a standard component of every Schubert TLM packaging machine, and is executed without the need of a switchboard cabinet. This is not only a space-saving feature. It ensures optimal machine performance over the entire service life and maximum flexibility.

In the future, Schubert will supplement its TLM packaging machines with a data box. It is the first stage of the emerging digital platform called “GRIPS.world”. This newly developed data manager for sophisticated packaging and manipulation solutions has been designed to improve internal communication and communication with customer components. And it is going without saying, that this will increase the overall efficiency of packaging lines on a sustained basis.

Schubert has already been demonstrating the flexibility of its high-performance technology at INTERPACK trade fair in Dusseldorf, Germany. And the next showcase will be the upcoming giant DRINKTEC exhibition in Munich. At the Interpack, Schubert has been exhibiting four brand-new Schubert TLM packaging machines that pack confectionery and cosmetic products.

New Competence Team for Cosmetics Filling and Packaging Solutions

In addition to the so called flow module – the new tube bag set from Schubert – visitors could also find a new TLM carton erecting system which defines a new benchmark in terms of performance and format conversion on smallest footprint possible.

The Schubert Group is celebrating a premiere with the presentation of the new competence team, Schubert-Cosmetics. Under the umbrella of SPS (Schubert Packaging Systems), the expert for plant engineering and engineering consulting, the company group now also bundles and strengthens its expertise in the field of cosmetics manufacturers.

The new data box will provide even more detailed and accurate feedback, thus facilitating maintenance and plant management. As an example, the error notification function indicates that a lift tube needs to be replaced.

GRIPS – The Next Step of Digitization in Packaging Machines

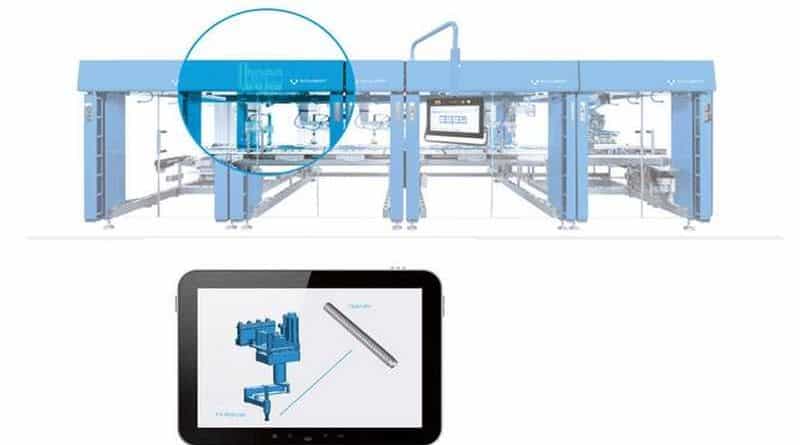

At this year’s Interpack, Schubert presented its new data box and possible applications of the future platform GRIPS.world. This web-based platform combines all the important functions for the monitoring and documentation of the machine data under a single user interface.

At GRIPS.world, customers, suppliers and the TLM machines themselves will be able to directly access the Schubert Group central maintenance and technical support service team via secure online connection. One component is the data box, which not only collects, but also directly analyzes important machine data.

The data box provides the machine manufacturer as well as the machine operator and their maintenance and plant management teams with an advanced interface to retrieve relevant information on various areas of the machine status. These are maintenance, control parameters and machine performance, just to name some examples.

From the data, valuable knowledge can be derived in the future that improves machine performance and customer processes. For example, in the long term, through the preventive maintenance and monitoring of the machine functions, the data box allows an increase on overall system efficiency and production performance to be maintained at a high level throughout the entire life cycle.

Preventive Maintenance, Plant Management and Machine Operation – almost infinite possibilities

A central element will be the “digital twin” of the machine, as Schubert puts it. This is a three-dimensional image of the TLM machine which can be moved in real time using the original code of the packaging machine controller VMS. The advantages of this are significantly accelerated design sequences, improved possibilities of maintenance, tele-service abilities and preventive maintenance as well as shorter delivery times for spare parts and required modules for example.

At the same time, for example, it will be possible to carry out the complete validation of a pharmaceutical machine in advance digitally. It is also possible to use the digital twin to perform new product formats. “The possibilities of the new system are really tremendous.” as a Schubert development engineer puts it. “Even we do not know all uses and new features this system may be providing over the coming years.”

Topic: GRIPS digitalization: Schubert flexible robotic packaging solutions go digital. Modular robotic packaging and product manipulation machines made in Germany.

Source: Schubert press release and own research.

Image credits: ©2019 Gerhard Schubert GmbH