KHS and Schubert Advanced Block Solutions For Flexible Packaging

Schubert and KHS present integrated block solutions for beverage manufacturers

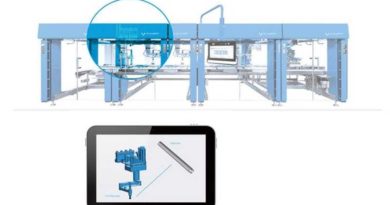

At the Drinktec 2017, Schubert will present a newly combined and interlocked packaging system called Innopack-TLM together with the partner company KHS. This plant enables outstanding possibilities in flexible packaging tasks, especially for the beverage industry. The new block is a seamless unit, that combines a Schubert TLM packaging machine without any interfaces with an integrated robotic KHS PPZ packer.

This solution enables highest packaging format diversity with little space requirement. Customers from the beverage industry benefit from a total and complete solution. This combined packaging machine concept leads to considerable increases in packaging quality and packaging flexibility.

The Innopack-TLM from Schubert and KHS can be used to pack numerous different bottle and end pack formats efficiently even in tight spaces.

Use of advanced robotic technologies in packaging machines

The system is based on advanced robotic technologies combined with transfer modularity. Everything is compressed into standardized modules that can be merged and extended at any given time according the a bottlers needs.

At the Drinktec exhibition in Munich, Germany, from 11 to 15 September 2017 Gerhard Schubert GmbH and KHS GmbH will present the advantages of the Innopack-TLM block solution at the KHS stand (Hall B4, Stand 328). The inline packaging system connects the machines of Schubert and KHS by connecting individual modules to a compact and space-saving unit.

The plant shown at the fair consists of five TLM sub-machines (modules) from Schubert and a bottle and crate packaging machine part from KHS. The plant block, commissioned by an Israeli brewery, is filled with 6 base baskets with 0.33 l bottles in a wrap-around carton or 6 base baskets with 0.5 l bottles in crates.

Seamless integration of robotic packaging modules in one single packaging unit

The interface-free connection between the KHS packer and the TLM packing system from Schubert is made possible by the use of the digital Databox system and the Transmodule. This patented transport robot takes care of the transport of the erected cartons into the KHS system and then transports the cartons filled with bottles to the corresponding modules for gluing and sealing.

The multi functional machine is clear, optimally accessible and compact. The entire system block is operated centrally via a single control terminal. Despite the versatility of this solution, personnel requirements are low – one person will be sufficient to operate the compact system, including feeding of packaging materials.

The system can be equipped with plastic beverage crates as well as carton baskets, carton clusters, wrap around cartons and other cardboard packaging. The plant combination presented at the trade fair in Munich achieves an output of up to 48,200 bottles per hour and thus up to 134 6 base baskets or 45 crates or cartons per minute.

Future-proof modular concept – Adaptable to new market requirements

This new combined flexible robotic packaging machine called Innopack TLM by Schubert and KHS is a breakthrough flexible packaging solution for breweries and for the complete beverage industry. The space-saving solution can be extended flexibly, thanks to the modular design.

If at any given time in the future the production volumes of a company will increase or the formats and product compilations should change, the system will be ready for it by the ability for modification or extension.

This allows customers to react quickly to changing market inquiries and will position the bottling companies well prepared within an increasingly competitive future.

Source: Schubert press release and own research.