Preventive Maintenance with Vegas Maintenance Platform

Digitally networked sensors record more and more machine data. With the vCare maintenance platform from Vega Grießhaber, these can be precisely read out for diagnosis and maintenance.

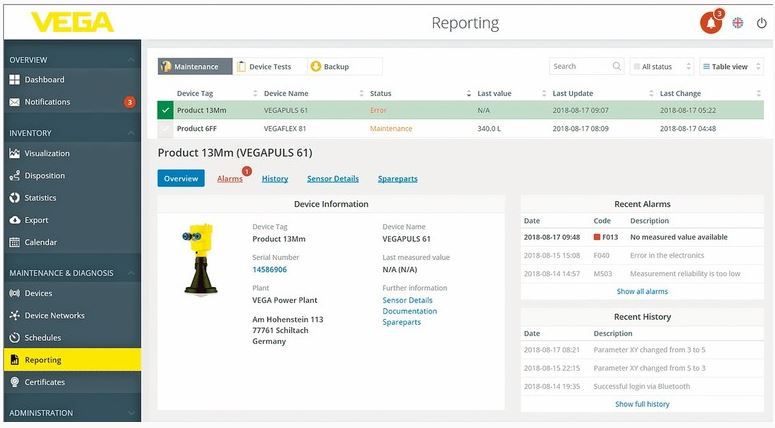

The user can decide which of these he wants to see on his screen: Device status, alarms, a calendar overview or history. This opens up potential for real competitive and cost advantages. The vCare service should be available from mid-2019.

Targeted Elimination of Downtimes and Malfunctions

Downtimes and malfunctions rank first in the process industry for machines and systems in terms of economic challenges – closely followed by downtimes due to cleaning or set-up. In increasingly complex plants, it is also becoming more difficult to see through errors, and the search for them is becoming more laborious.

Digitally networked sensors have the potential for real competitive and cost advantages for this task. Always provided that their data is read out accurately for diagnosis and maintenance: Ideally, they should be personalized and appropriate in terms of content. Are device status, alarms, a calendar overview or history required? On the digital maintenance platform vCare, the user decides what he sees on his screen. This provides scope for further development as the range grows.

The opportunities for the process industry arising from the digital connection of its operative production world and the communicative IT world in the cloud are already evident in a few facts. Machines are maintained before an expensive malfunction occurs. Cleaning and set-up times are constantly optimized and flexible production is available at almost the same conditions as mass production.

The fine line that has to be mastered lies between the willingness to innovate and the cost risk. Many industry 4.0 initiatives generate possibly high investments, which in the end slow down development. Because not every company has a need for all disciplines or has to master all skills. Rather, it is important to identify what is really needed and focus on the modules that bring real benefits.

Intelligent systems full of information

Field devices are intelligent systems in themselves and are full of important information – both about the processes in which they are used and about their own status. How this data is used and how it can be integrated into control systems is up to the user to decide. In the best case, the devices determine process-relevant data and visualize them clearly. Downtimes can be effectively minimized by predictive maintenance and repair.

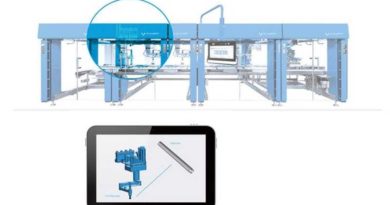

However, these data must first be made accessible. Especially in extensive plant areas, at distributed or mobile production sites and applications, communication via Bluetooth can prove to be an important bridge technology to the industrial 4.0 plant. Vega therefore already offers wireless transmission as an option for all sensors with Plicscom displays and thus almost its entire sensor portfolio. Because the technical requirements are modular with a view to future developments, this means that Bluetooth can be easily integrated retrospectively for the majority of all Vega sensors on the market.

Integrating and automatically connecting additional field devices

If a range of 25 to a maximum of 50 m is desired, access to the field device is hardly easier and, above all, cheaper to think of. There are no licence fees for Bluetooth. The communication option is global, available on the ISM band at 2.4 GHz. Because their roots lie in the consumer sector, the terminals required for system operation are already available at countless locations.

Other field devices can also be easily integrated and automatically connected. In addition to transmitting measured values, Bluetooth enables the transmission of alarms for critical values and the remote configuration of systems. Everything conveniently via PC or smartphone. The result: decisive cost savings for service calls and better control over the entire field equipment. Advantages that pay off immediately.

With the monitoring of process and device data by the maintenance platform vCare, Vega offers a growing concept to make the information streams required for industry 4.0 flow. The focus here is on simple feasibility. This is already expressed by the use of the simple and the proven. Techniques and components, which we know from our daily life, wireless and wired transmission possibilities as well as Smartphones or Tablets belong to it.

Central maintenance and monitoring platform

As a central maintenance and monitoring platform, embedded in the user portal myVega, vCare displays all important sensor information clearly on the PC screen. The data is anchored in the protected cloud. The platform provides process information, but filtered according to relevance or preference and differentiated according to the respective sensor.

It provides alarm messages and suggested solutions, but at the right time to operate plants economically and with foresight. And it provides general device information, but without annoying reference. What’s special: Specific information remains specific – suitable for the respective device. General information is available in the form of easily understandable add-ons. Additional information can be “booked” flexibly on the vCare platform as required.

Data Transmission and Cloud Security

Security is very important for data transmission and in the cloud, as sensitive user data is always involved. That’s why Vega has implemented extensive security measures. Before data transmission begins, device communication is encrypted and devices are authenticated in the network. With the digital offer “PINs & Codes”, device access data can also be stored and protected centrally in the portal. If an operating device fails, PINs & Codes enable the user to continue working without having to re-enter data.

In the background, the access data of all sensors are automatically synchronized by logging on to the myVega portal once. Additional operating devices are automatically synchronized and can immediately access all sensors. This allows digital networking to be set up step by step. Initial practical experience will show what exactly offers safety or a real competitive advantage. On this basis, it will then be possible to continue comfortably and in the right size with minimized risk.

Source: VEGA.com press release article